Our Story

Early

1980s

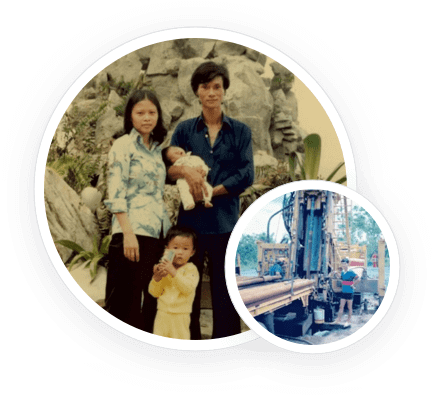

Originally from Saigon Vietnam, the Hua family was involved in making industrial equipment to process tea, tobacco and rice. Thang Hua took the risky decision to flee Vietnam with his pregnant wife and 2 year old son on an overcrowded fishing boat. During the trip, they were robbed by pirates and his wife gave birth on the boat the night before arriving in a Malaysian refugee camp. The Hua family migrated to Australia as refugees, spending some time in the Wacol detention centre before settling in Brisbane’s West End.

Thang supported his young family by sweeping floors at Warman International, a large mining manufacturer. With little English, Thang was able to prove himself and demonstrate his machining skills that he learnt back in Vietnam. He took every opportunity to learn new skills and progressed quickly. He mastered many machines and processes and was known for his speed and quality. He eventually gained his trade certificate as a qualified fitter and turner and earned respect amongst his new Aussie work mates.

Late

1980s

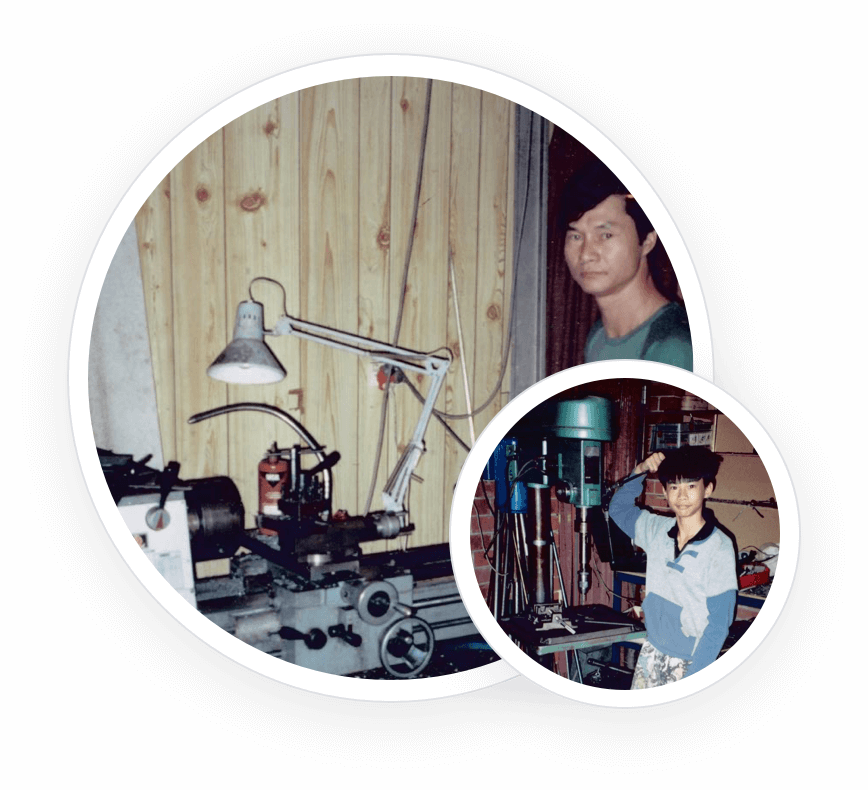

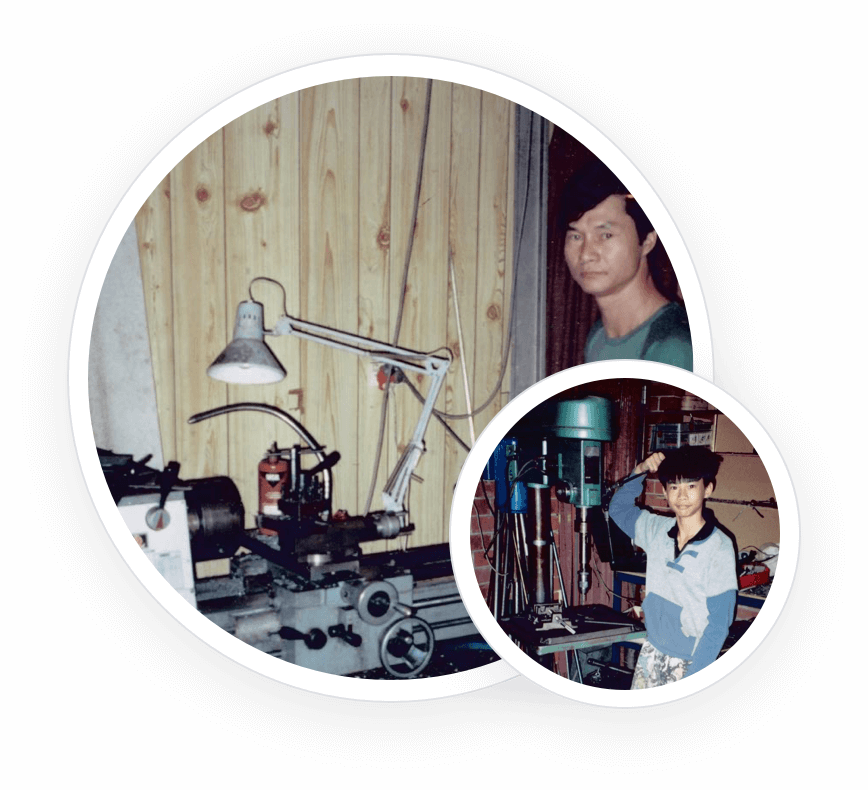

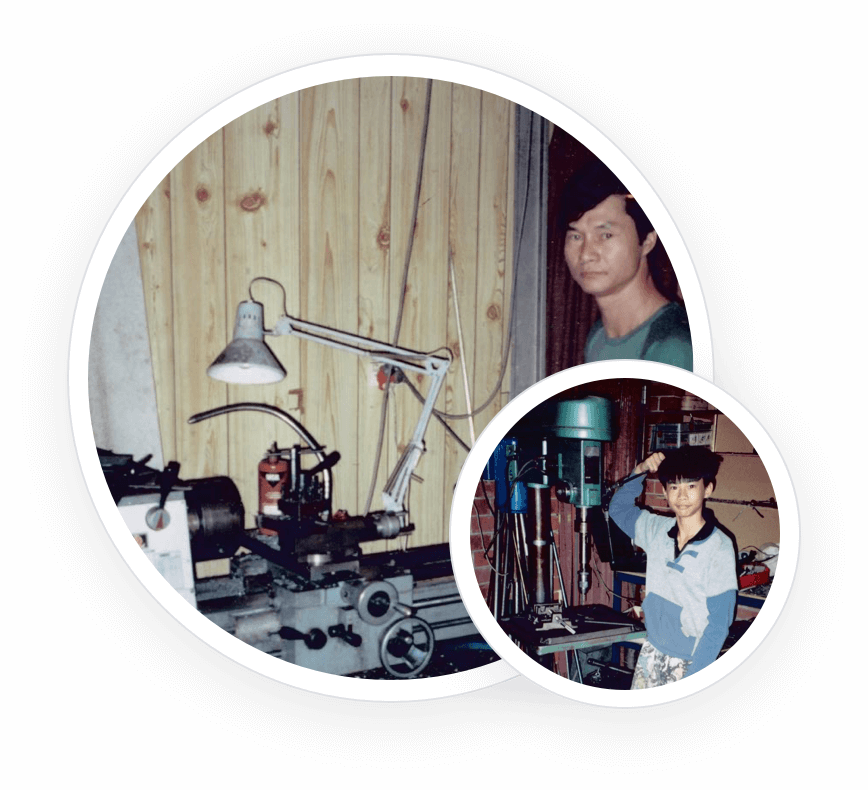

When Thang was made redundant in the downturn of the late 1980’s, he invested in a small Lathe and a basic drill press which would allow him to do contract work for his former employer.

This simple 6 inch metal lathe from Taiwan was set up under the family’s West End home. This was the founding machine that would create TNN Engineering.

Both Tin and brother, Le recall cleaning and oiling the machine as part of their daily chores and this same machine is still in operation today. The whole family helped where they could, and the sons started learning the trade from an early age.

The business became a full-time job in 1990 and was trading under the name of TNN Light Engineering. T from Thang and N N from Nu Nguyen.

1994

The garage under the suburban house in West End could no longer hold the growing number and size of machines. The family and business were relocated to a rural property in Richlands. A slightly larger garage was temporarily used while a 200 sqm purpose-built shed was erected. The business was changed to a company structure – TNN Engineering Pty Ltd

1996

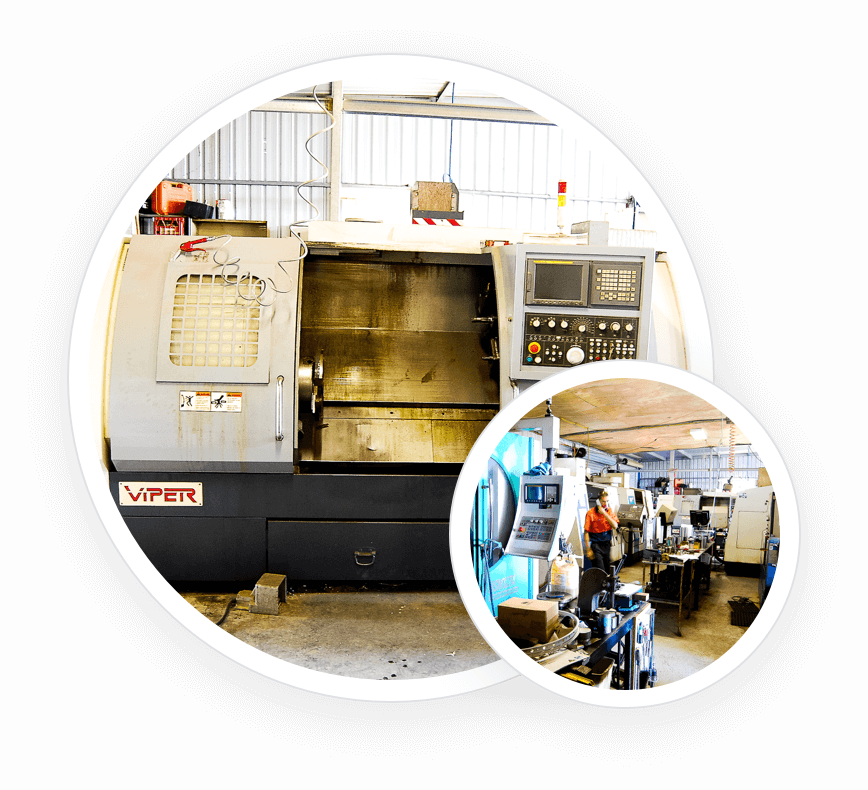

The larger shed allowed them to purchase their first CNC machines – a Hurco CNC mill and a Hyundai CNC lathe. At the time each machine cost about the same as the average house. This was a significant investment in technology and capability for TNN. It was also a steep learning curve to become proficient at programming and operating these precision machines. One of the first marketing campaigns to help justify the CNC investment, were photo business cards and later the creation of the first TNN Engineering Logo.

2004

As TNN grew so did their operations. By 2004, TNN added two more CNC machines to the fleet. A larger three axis CNC lathe and a larger four axis CNC milling machine. This required an extension to the original shed. Due to significant growth and new opportunities, Tin returned to the business in a management role. Prior to this, he had gained his degree in Mechanical Engineering and had been designing and testing vehicle accessories. Thang Hua was now starting to hand over the day to day operation of the business over to the two sons.

2006

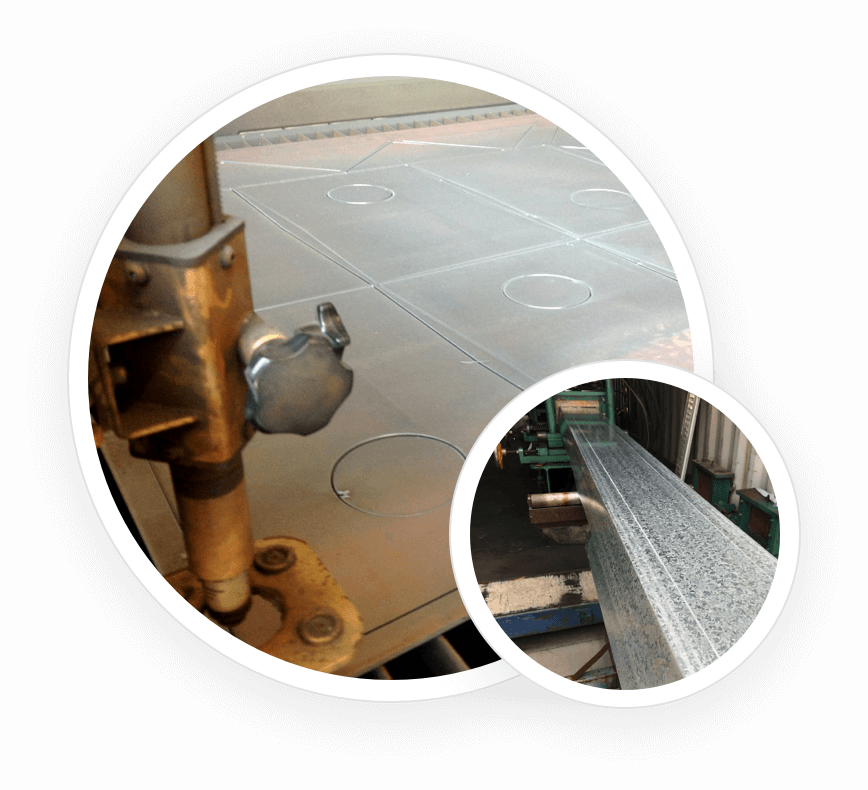

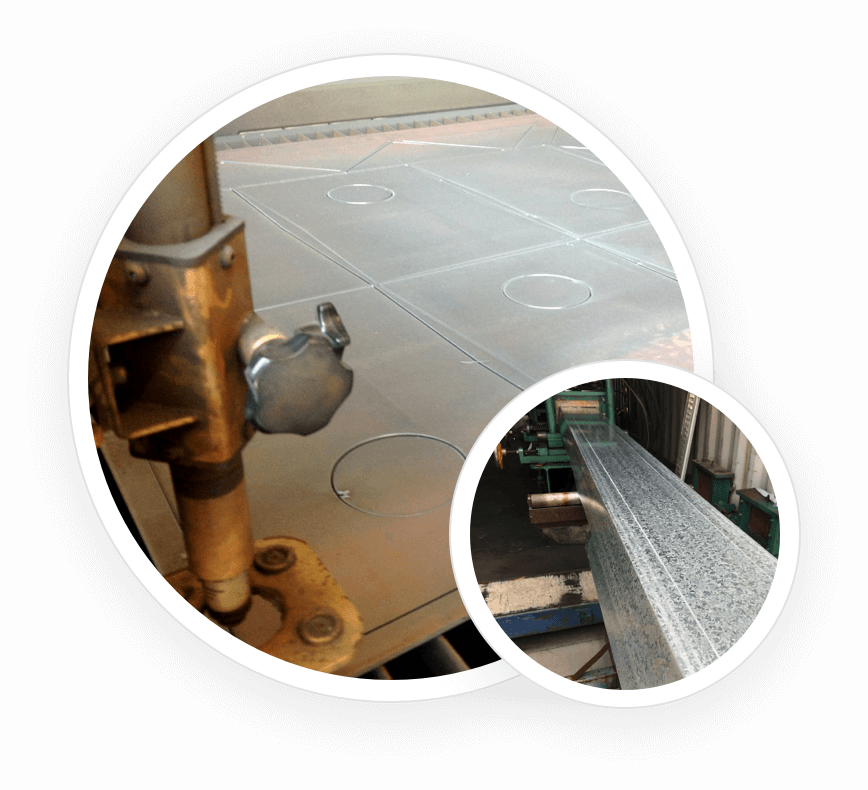

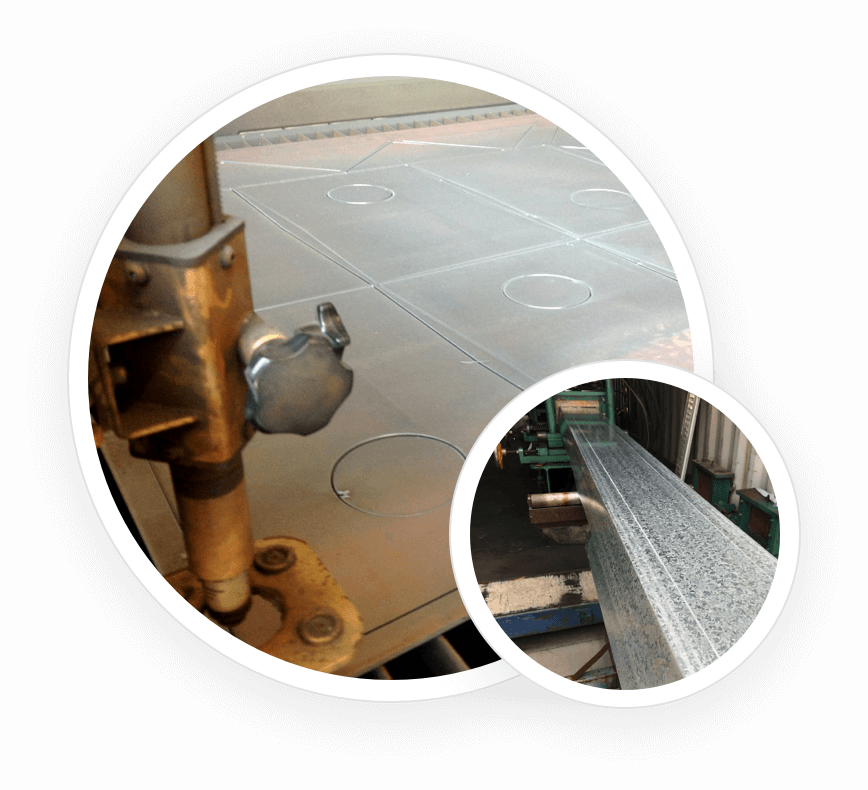

TNN Commissioned a CNC Plasma cutting machine and another Hurco CNC milling machine. The business now offered steel fabrication and welding of small to medium sized component. TNN supplied products and services to the civil construction and concrete precast industries. Another opportunity saw the purchase and commissioning of specially designed roll forming machines to produce gutters and film clips for the construction of protected cropping greenhouses.

2007

Thang Hua was now semi-retired and the TNN team had grown to 12. The business was moved to a new entity – TNN Engineering Australia P/L. An ERP system , M1, is deployed to manage the entire production process from quoting to invoicing, providing improvements in quality and resource efficiency.

2008

TNN invested heavily in a new 5 axis, dual spindle CNC multi-tasking lathe, bringing the total number of CNC machines in the fleet to 9.

2010

TNN had outgrown their premises at Richlands and re-locates to a 4000 sqm facility in Carole Park.

2011

Commissioned two more HURCO CNC milling machines boasting touch screens and 3d animation. These extra machines allowed more flexibility and quicker setup times.

2015

New fresh branding and logo for TNN Engineering. Commissioned a new Hyundai CNC lathe with bar feeder for high volume production.

2018

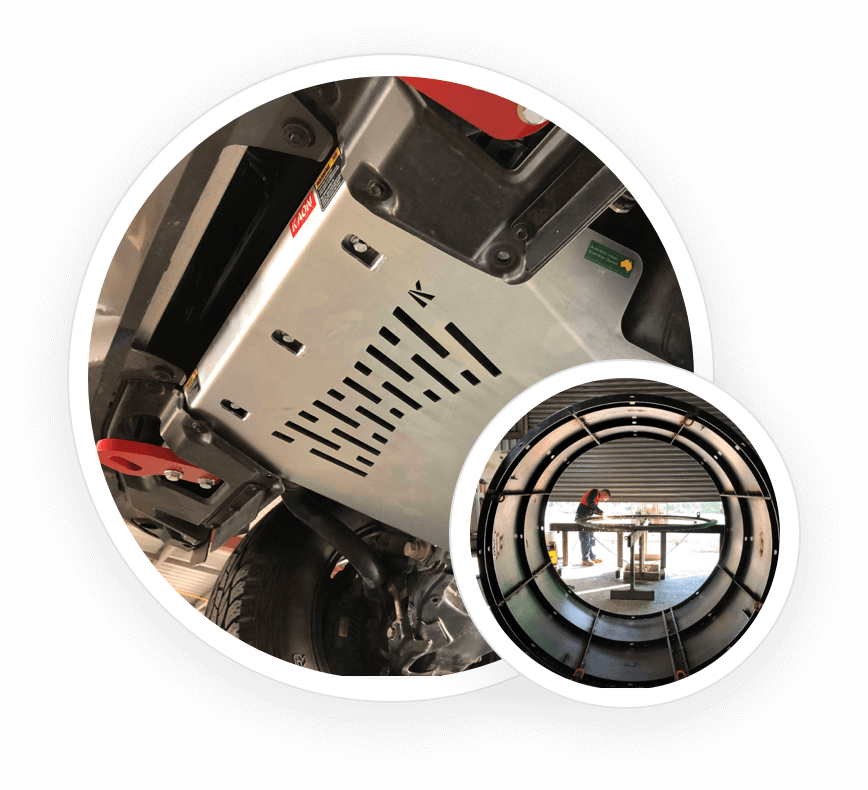

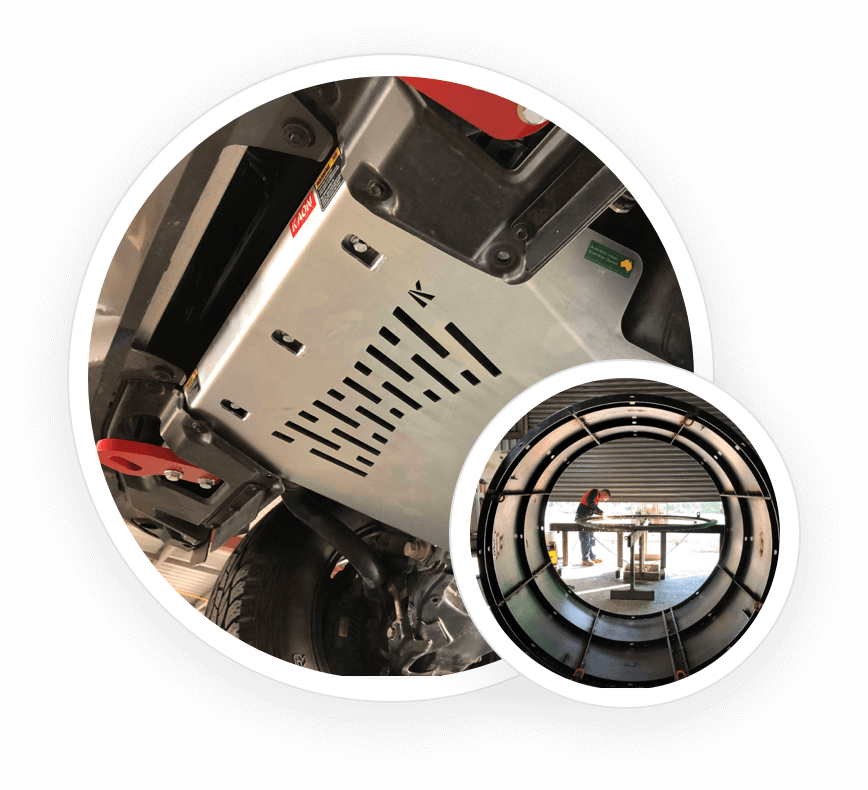

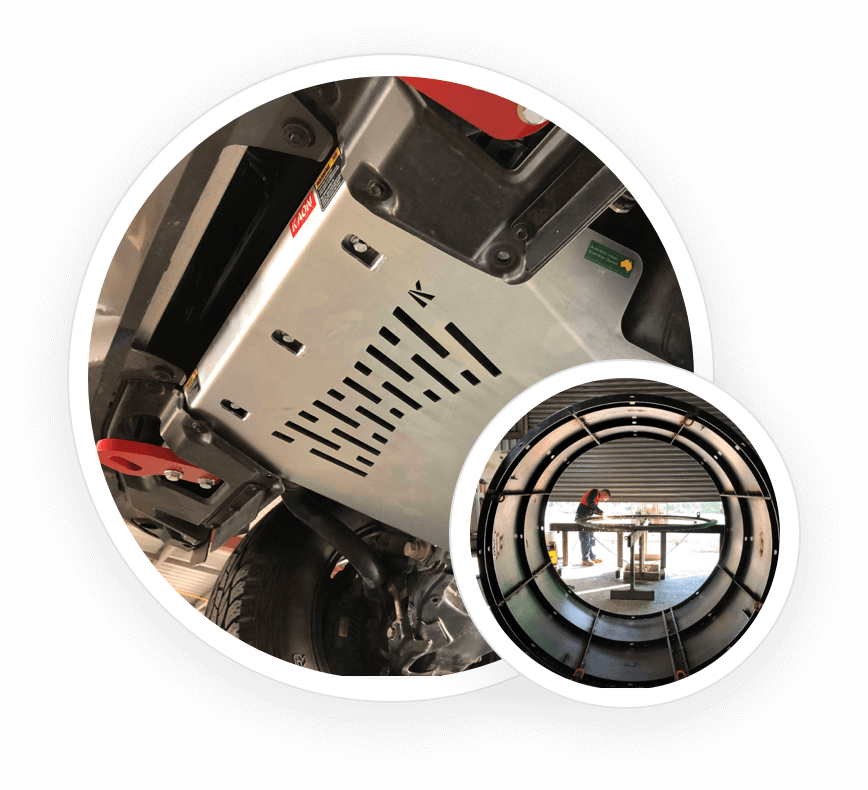

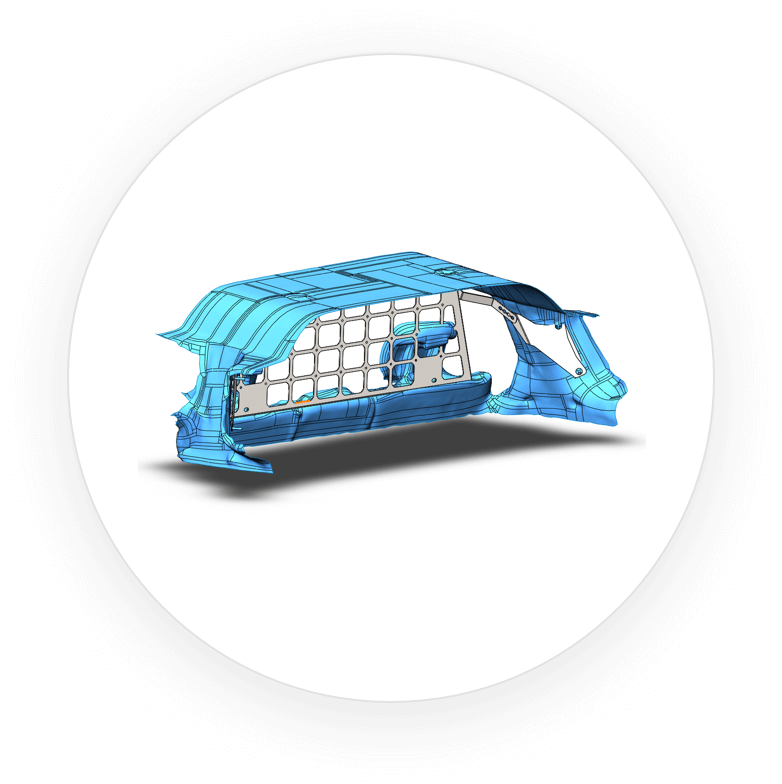

TNN operations have diversified into 4×4 accessories and concrete formwork. TNN gains ISO9001 quality certification.

2019

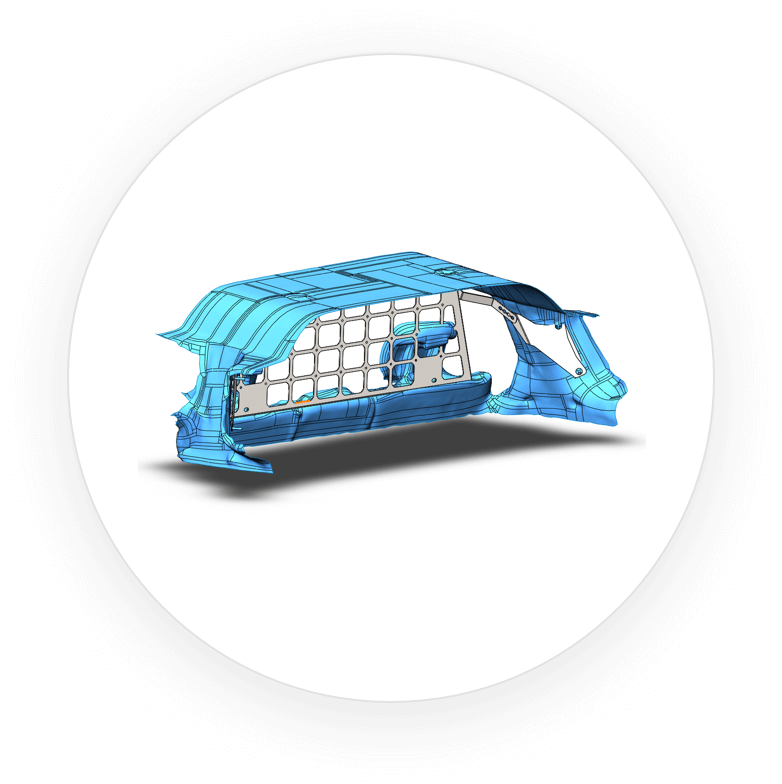

Investment in new CAD software and 3D scanning. The team continues to grow with a focus on training and developing the next generation of skilled tradespeople.