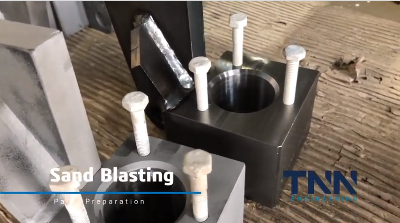

Special “sand” and grit is blasted at the surface to remove rust, scale and to provide an even uniform surface which is an ideal preparation for painting or powder coating. Areas can be selectively blasted by masking off areas with blast tape or special covers and fixtures. This is required when high precision machined surfaces need to be protected so that the surface finish and tolerances are maintained.

This process is also used for cleaning up surfaces after heat treatment or brazing. It removes soot, excess flux and heat marks.

Sand blasting can also be used for cosmetic purposes. It leaves a dull uniform finish and removes most machining marks.

It is also recommended as a surface preparation for gluing of parts. The blasting process provides a rough textured finish with more surface area which is ideal for most gluing applications.

At TNN, we can process small to medium parts. We can also arrange blasting of large components such as car bodies and truck trays.