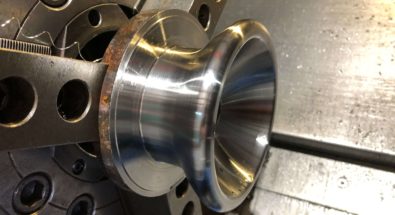

CNC lathes are computer-controlled machines used for processing parts that require cylindrical turning operations. Components such as pins, bushes, flanges and shafts. They are fast, efficient and very accurate. They will consistently and reliably produce parts to tolerances of 10 microns or 0.01mm while leaving a shiny and smooth surface finish. TNN Engineering have a range of CNC lathes suited for both small run and higher quantity production runs.

TNN Engineering machine shop in Brisbane invested in their first CNC lathe in 1994 when we recognised the advantages that this technology could offer our clients. These machines are designed to be precise, fast and repeatable and could take advantage of the new cutting tools that were becoming available. The tools used to turn and cut metal have changed dramatically in the last few decades with new cutting grades, coatings and methods. To take advantage of these improvements, CNC lathes have developed and evolved allowing substantial improvements in quality and production efficiency.

The spindles are engineered to be fast and stable both during machining and during rapid changes in spindle speed. This means higher cutting speeds and reduced cycle times. The tool is moved relative to the workpiece by powerful, fast and accurate servo motors. The tool can be moved at speeds of up to 30 metres per minute. Less time moving the tool into position increases the proportion of time spent cutting the part which reduces cycle times.

Holding the workpieces in place are precision high pressure hydraulic chucks which allow for higher cutting speeds and feeds. Work pieces can be loading manually or with automatic bar feeders for un-manned production. Lightning fast tool changers allow the machine to select the appropriate tool for the operation required to complete the part. Operations such as external and internal turning, hole drilling, threading and grooving. CNC lathes with C-axis and live tooling can also complete basic milling and drilling operations in the one setup.

For longer parts such as rollers and shafts, the part can be placed inside the spindle bore or supported using a live centre. Our machines can take parts as large as 90mm through the bore of the spindle or can support shafts as long as 1500mm using a live centre.

| A wide range of materials can be machined including |

|---|

| Common engineering steel. S1214, 1020, 1045, 4140 |

| Hardened steel upto 55Rc |

| Aluminium |

| Stainless |

| Brass, Bronze and Copper |

| Engineering Plastics such as Acetal, Nylon, Polyurethane |

We have a range of CNC lathes which allows us to cover a wide range of turning operations.

| Hyundai 210 |

|---|

| This is our general purpose 2 axis CNC lathe with bar feeder. It is quick to program and setup and is ideal for one off and small production runs. |

| 62mm bar through bore capacity |

| 380mm diameter x 500mm long turning capacity |

| 8 station tool turret |

| Programable tail stock |

| Bar Feeder and Parts Catcher |

| AlexTech Viper VT30 |

|---|

| This is a versatile 3 axis CNC lathe with bar feeding and milling capability. |

| 90mm bar through bore capacity |

| 450mm diameter x 1000mm long turning capacity |

| 12 station tool turret with live tooling |

| Drilling, tapping and milling |

| 65mm x 1500mm long bar feeder |