CNC machining centres are computer controlled milling machines. They are highly versatile machines and come in many configurations. They perform operations which require the tool to rotate relative to the work piece. Operations such as:

| Drilling |

| Countersinking |

| Boring |

| Tapping and thread forming |

| Face Milling |

| Edge Milling and contouring |

| Bevelling |

| Engraving |

These machines are equipped with automatic tool changers which allows wide range of tools to be used for any one component. This allows for automatic operation, no longer requiring an operator to be stationed at the machine while it is running.

To cater for small batches and quick response times, we have chosen CNC machining centres that are quick and easy to program and setup. We have several machines featuring controllers with powerful and easy to learn conversational programming. They have 3D graphics and toolpath simulation to verify programs before any metal is cut. Another advantage is that we can easily optimise the program and make quick changes at the machine to improve quality and reduce run times.

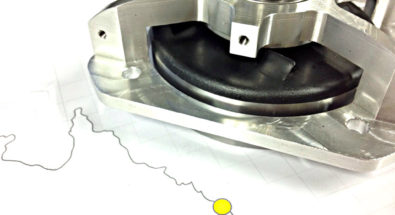

For more complicated components we use offline Computer Aided Manufacturing (CAM). This allows us to program and verify tool paths before sending the program to the machine. We can machine complex 3D contours and shapes from 3D files supplied by our customers.

3D machining allows flexibility when machining bevels and weld preparations at angles other than 45 degrees. Combined with high speed machining practices, we can make economically machine these features in a wide range of materials.

We the latest cutting tools and technologies such as solid carbide coated endmills, high feed cutters and indexable insert milling tools. This allows us to machine a wide range of materials including.

| Mild steel plate eg G250 |

| Bisalloy and equivalent wear plates upto Bisalloy 400 |

| High tensile steel and tool steel such as 4140 and K110 |

| Aluminium |

| Stainless Steel |

| Cast iron and SG irons |

| Brass, Bronze and Copper |

| Engineering Plastics such as Acetal, Nylon and Polyethylene |

We also have 4th Axis rotary milling capability. This allows us to rotate the part while milling which can reduce step times and improve accuracy.

Engraving for part identification is something that can easily be achieved on our CNC Mills. We can engrave part number, serial numbers or purchase order numbers. We can also engrave logos and symbols and markings as required.