Laser cutting uses a focused beam of light to cut sheet and plate material. TNN Engineering partners with laser cutting suppliers to complement our in-house processes. This allows us to provide a wide range of laser cutting and metal folding services in Brisbane.

| Materials that we process include: |

|---|

| Mild Steels – 250 and 350 grade |

| Wear plate – Bisalloy 80 and 400 |

| Stainless Steel – mill and brushed finishes |

| Aluminium |

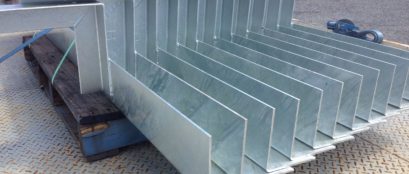

Lasers provide a very accurate and clean cut in thickness of up to 20mm. Accuracy is within +/- 0.10 mm and cut edges are crisp, square and free of slag. Laser cutting is ideally suited for sheet metal and light plate processing. Slots and holes can be cut accurately as well as any internal and external shapes. Once cut, profiles can be pressed and shaped into brackets, covers or boxes. We also offer secondary process such as welding, tapping, machining and surface coatings. We also have access to tube laser cutting of pipe and RHS sections.

At TNN Engineering Brisbane, we utilise the best pressing technology to provide accurate metal folding services. With over 30 years of experience in metal folding and laser cutting, you can feel confident getting your metal cut, formed and folded all at the same place.